More and more people are beginning to own the first or even second iPhone as a result of the widespread use of cell phones. The iPhone screen will fall if it malfunctions multiple times when a cell phone is used for a prolonged period of time and always fall from the hand to the ground. Many folks spend several months’ worth of wages on one iPhone. Everyone will choose to replace the iPhone screen rather than the complete device given the exorbitant expense of purchasing a new iPhone.

However, very few people have regular access to the phone screens. How can you choose a decent iPhone LCD screen when it can be difficult for average people to tell the difference between good screens and terrible panels? Today SensePluz LCD Factory will be popularized for everyone.

The raw materials used to make cell phone screens, which have a different quality and cost depending on the supplier, the production environment for cell phone screens, which includes the temperature of dust-free workshops, humidity, and anti-static treatment, as well as the cell phone screen’s quality inspection, are the main factors influencing the quality of cell phone screens.

Furthermore, the completed item trial of the quality assessment division is additionally vital, and a few flawed items will influence the nature of the entire clump of merchandise. The packaging of the mobile phone screen, as the screen is relatively fragile and more scared of collision. If it is not packaged, it will shorten the lifespan of the phone’s screen.

Today SensePluz LCD Manufacturing plant needs to enlighten you concerning the effect of creation processes on mobile phone screens. Prior to presenting the creation cycle, we will initially give you a few industry terms: GFF, GG, OGS, Incell, Oncell.

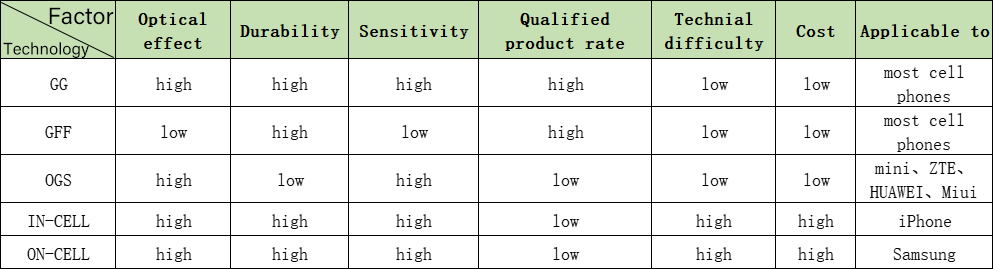

Advantage and disadvantage for each technology

G+G (glass lens+ glass sensor): Just a single glass sensor, ITO glass in rhombus design to support touch in multiple points.

G+F+F (cover glass+ film sensor+ film sensor): Two layers films sensors, ITO glass in rhombus design to support touch in multiple points.

OGS (one glass arrangement): Laminate the glass and touch screen to form one piece. People can directly coat and photo etch on glass that has been coated with an ITO conductive layer. This LCD display will be more affordable and slimmer.

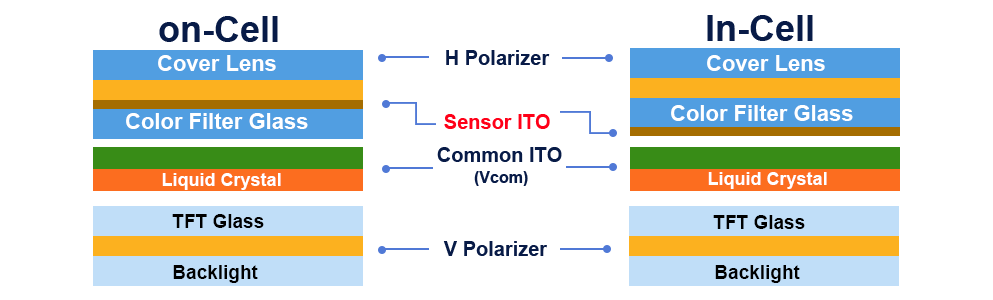

In-Cell: Touch panel with ITO sensor inside a color-filtering cell.

On-Cell: Between a polarizer and a color filter glass, an on-cell touch panel with an ITO sensor is used. Compared to in-cell technology, this technique is a lot simpler.

The most common cell phone technology at the moment is G+G, and the screen stability is also improved. G+F is the technology that will be promoted in the future, and the development trend is expected to be fairly positive. At the moment, SensePluz LCD Factory is working hard to develop this technology.

OGS utilizes just a straightforward layer of film, which can cause security issues, and isn’t as of now broadly utilized.

The stability of the cell phone screen is not very excellent, and Incell and Oncell are still developing technologies with large costs. The technology won’t be fully developed for a very long time.

I trust this article can let you know several factors that affect the cell phone screen. We shall cover more expert knowledge regarding cell phone screens in the article after this. I sincerely hope that everyone will keep checking our website, www.sensepluz.com, for the newest cell phone screens and accessories, see you soon.